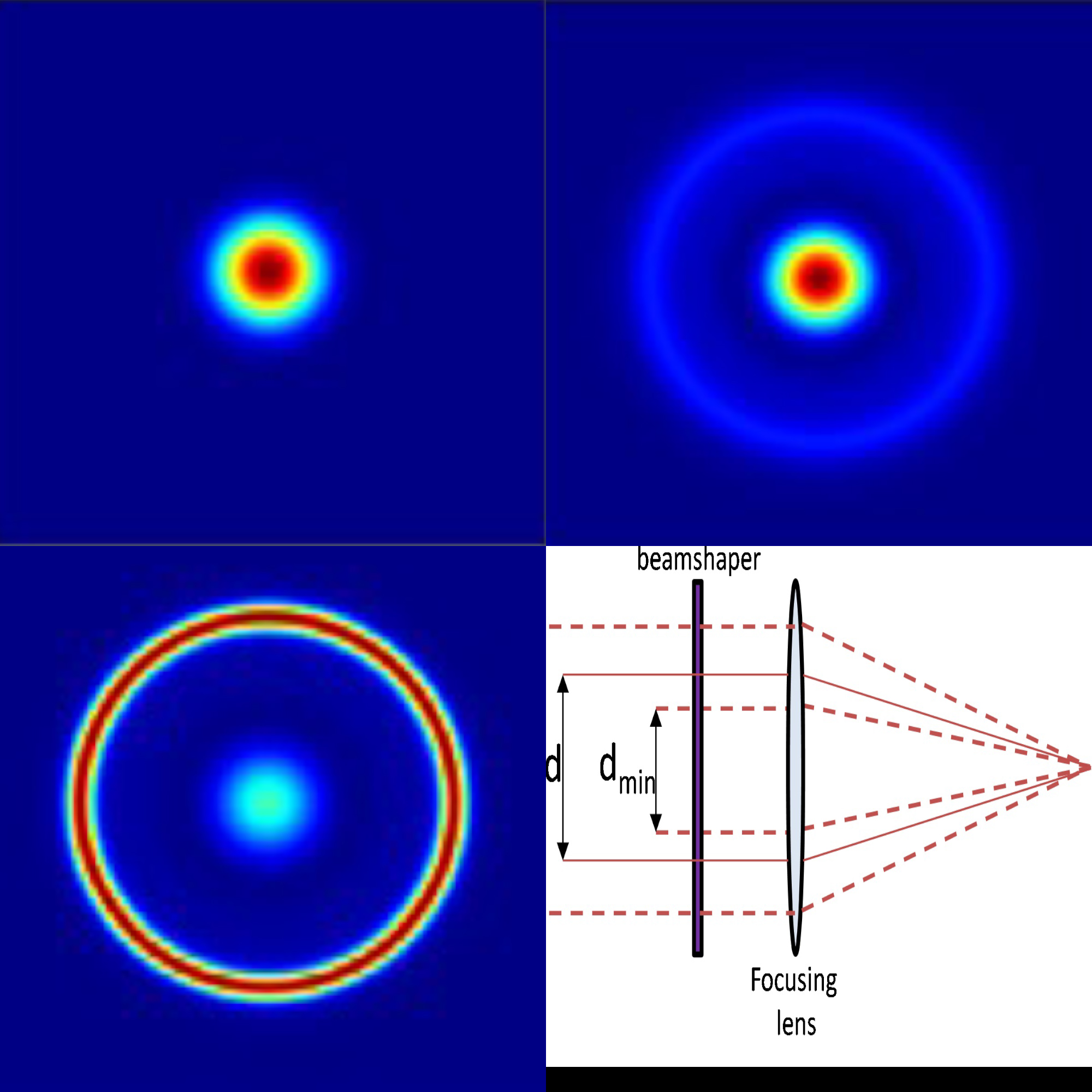

PowerPhotonic, designer and manufacturer of freeform, wafer-scale optics, will launch a revolutionary, new, Variable Beam Shaper at the SPIE ‘Sensors and Imaging’ exhibition and conference, in Edinburgh, later this month. The Variable Beam Shaper enables a single mode, Gaussian laser beam to be focused into one of three different output profiles; a Gaussian spot; a flat top circular spot; or a ring-shaped spot. Selection and tuning of the desired spot profile, and the smooth transition between profiles, is achieved by simply adjusting the input laser beam diameter.

Dr. Stephen Kidd, Head of Sales and Marketing at PowerPhotonic, said, “PowerPhotonic’s Variable Beam Shaper, being showcased at SPIE Sensors and Imaging later this month, is a far simpler and more cost-effective solution for variable beam shaping than currently exists. It enables many new market opportunities which were previously cost-prohibitive. The Variable Beam Shaper initial design targets applications in laser welding, additive manufacturing, and laser surface treatment. These include hydrophobic surfaces which repel water and other fluids. In medical applications, this can be used to create anti-microbial and anti-bacterial surfaces which are intrinsically clean. However, PowerPhotonic can also design and manufacture custom static or variable beam shapers for many other laser applications.”

The Variable Beam Shaper is made from fused silica with low loss and low scatter surfaces. These allow high-power handling from CW or pulsed lasers in the fs-ps-ns regime.

For more information about PowerPhotonic Ltd contact: