Optic Calculator Tools

Designing and manufacturing a high-performance micro-optic can sometimes be a daunting prospect. PowerPhotonic’s calculators will help you determine some of the key characteristics of the optical surface including lens specifications, manufacturability and beam quality.

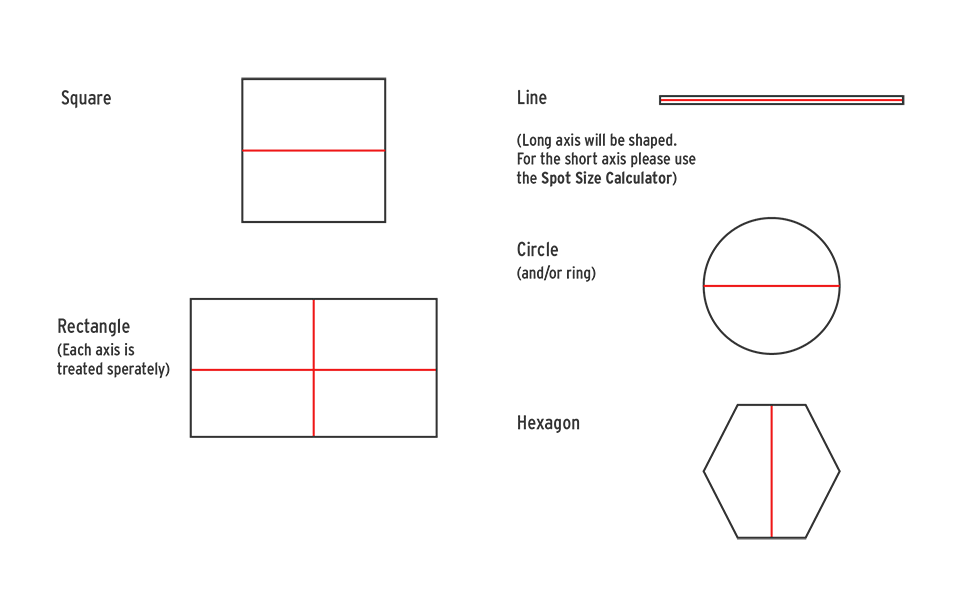

Lens Calculator:

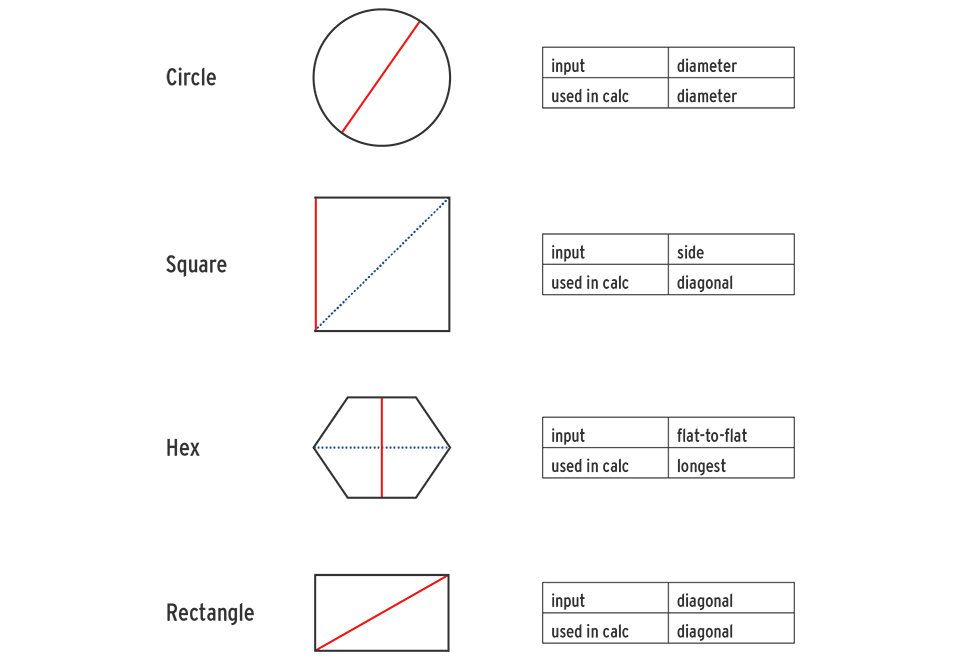

The lens data calculator determines some of the key surface parameters depending on the lens diameter and required focal length. The results can help determine if the required surface is manufacturable, and if not, what parameters need to be modified to bring the surface within the manufacturable range.

For more information about PowerPhotonic’s fabrication capabilities, see our website.

Spot Size Calculator:

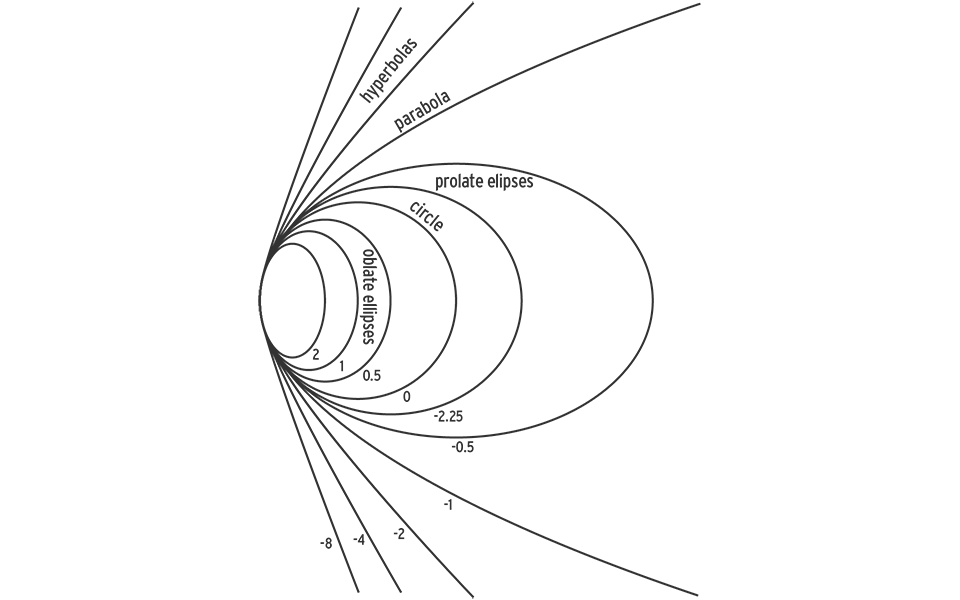

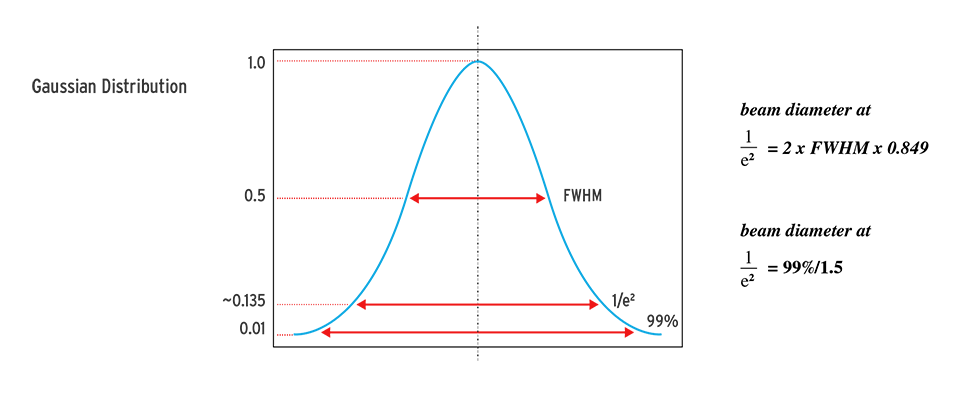

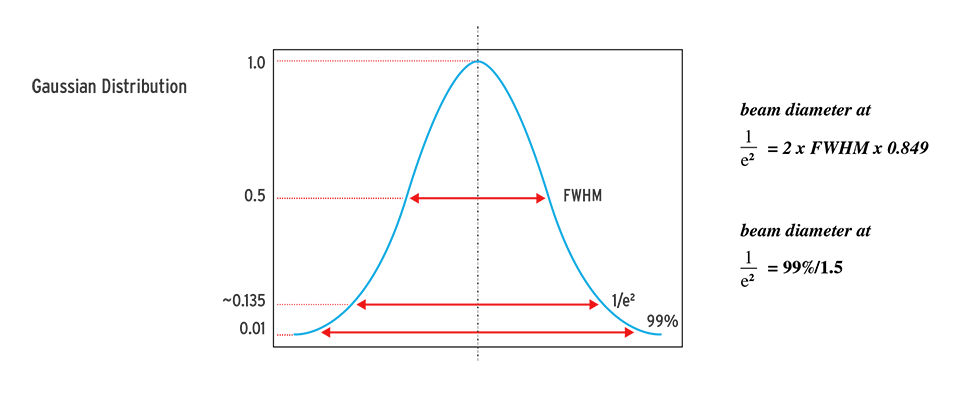

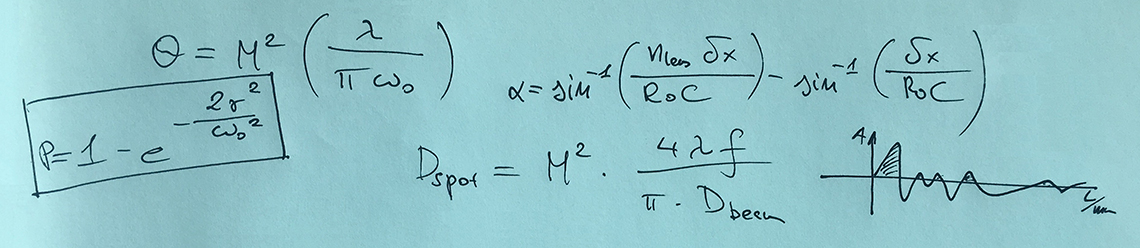

The ability of a lens to focus a beam of light into a small spot is limited by diffraction. This calculator will determine the smallest spot that can be created by a perfect lens with a gaussian input beam. The user can vary the input beam size, lens focal length and wavelength to assess how the diffraction limited spot size varies.

At PowerPhotonic, this information is used by the engineering team to determine the minimum size of a shaped beam. All beam shapers add divergence to the beam. Therefore, a shaped beam can never be smaller than the diffraction limited spot size of the system.

Beam Shaper Quality Calculator:

This calculator can be used to determine the likely quality of a single mode beam shaper optic. It is possible to calculate an indicator of beam shaper quality based on a set of optical train parameters. When shaping a single mode laser beam, the beam shaper optic will continuously map the input power distribution (Gaussian) onto the desired output distribution by changing the local surface slope. The beam shaper will always add some level of divergence, which means the shaped spot will always be larger than the diffraction limited spot size. The beam shaper quality indicator is a function of the ratio between the unshaped spot size and the shaped spot size.