Laser glass cleaving with ultrashort pulsed lasers is a non-thermal process that involves inducing stress in the glass through controlled fracture propagation.

The process involves focusing an ultrashort pulse onto the glass surface. This laser beam has a high peak power and a very short pulse duration, typically in the femtosecond range. Unlike thermal-based glass cleaving, ultrashort pulsed laser cleaving is a non-thermal process. A high-intensity ultrashort laser pulse is focused onto the glass surface, transferring energy to the glass and causing internal stress. The internal stress created by the expansion reaches a critical point and causes cracks to initiate at the surface or inside the glass. These cracks are typically formed perpendicular to the direction of the laser beam. Once the cracks have been initiated, they propagate through the glass, guided by the stress points. This path can be controlled by adjusting laser parameters, via beam shaping, and by the positioning of the laser beam. As the cracks propagate, they reach a desired separation point, resulting in the complete separation of the glass along the cleaving point.

Laser glass cleaving allows for precise and controlled cuts, with the ability to create complex shapes and patterns. Due to the clean and smooth cuts, additional processing and finishing is minimised. It can be used on various types of glass, including thin and brittle glass, without causing excessive damage or chipping. It reduces the risk of contamination, as there is no physical contact between the cutting tool and the glass, the risk of contamination is greatly reduced.

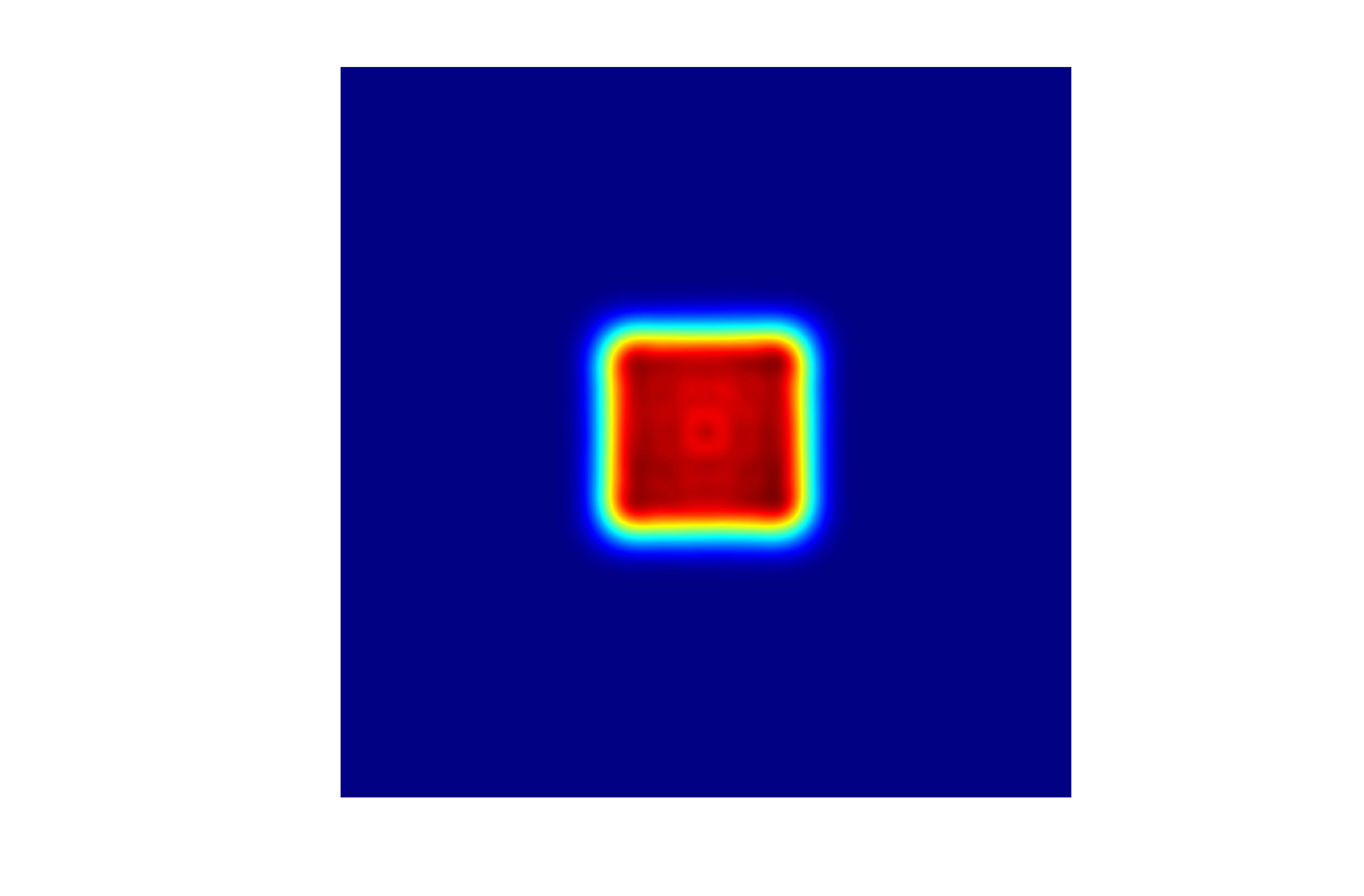

Using the PowerPhotonic Bessel beam shaper to precisely control the laser beam as it propagates through the glass, not only improves the cleave quality but can also allow for increased cutting speeds.