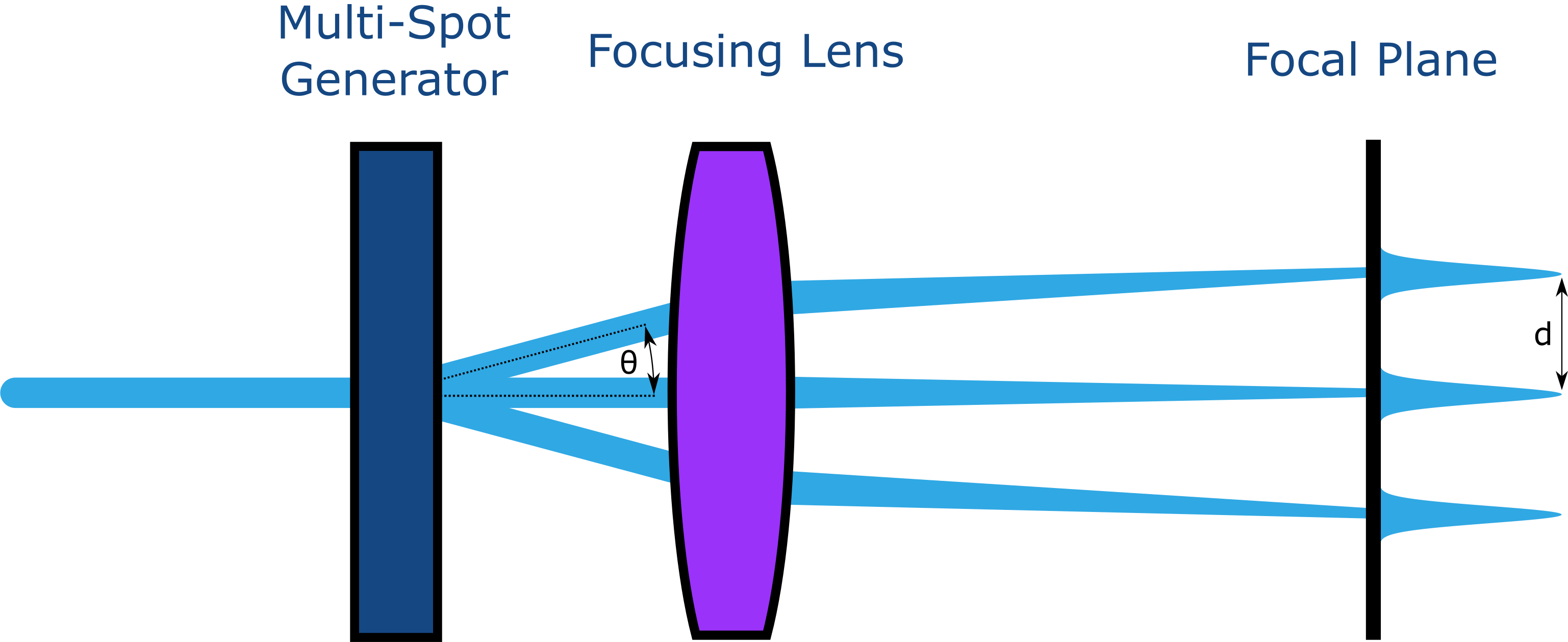

PowerPhotonic, designer and manufacturer of freeform, wafer-scale optics, has launched a new, Multi-Spot Generator which improves laser process efficiency and performance in a wide range of surface functionalization and additive manufacturing applications. The Multi-Spot Generators are a type of freeform optical element that produces an array of spots from a single mode, input beam. They are critical in parallel, laser processing applications, including laser induced periodic structured surfaces (LIPSS), which are hydrophobic, and multiple additive manufacturing (AM) applications.

Dr. Stephen Kidd, Head of Sales and Marketing at PowerPhotonic, said, “The structure of PowerPhotonic’s Multi-Spot Generator is produced using a unique, fused silica, freeform optics manufacturing process. It has conversion efficiencies far higher than traditional diffractive elements that use binary gratings, as well as maintaining good spot to spot uniformity. With extreme, low scatter, surface optics, the multi-spot generator has intrinsically high power-handling capabilities in both pulsed and continuous wave operation.”

Currently, PowerPhotonic offers Multi-Spot Generators which produce a 1D array of three spots or nine spots; a 2D array of three-by-three spots; and a hexagonal array of seven spots. However, the Multi-Spot Generator can be custom designed for specific input wavelengths, output spots and their separation.

For more information about PowerPhotonic Ltd contact: