PowerPhotonic, designer and manufacturer of freeform, wafer-scale optics, is achieving laser induced damage threshold (LIDT) measurements exceeding 100kW/cm at 1070 nm in continuous wave, high-power, laser applications. This means that a collimated laser beam of up to 100kW in power, and 10mm in diameter (determined as 1/e), can pass through a PowerPhotonic optical component without causing damage. This market-leading performance demonstrates the highest possible levels of laser optics manufacturing quality, enabling the delivery of world-leading levels of power in a range of laser applications, including defence, laser cutting, laser welding and additive manufacturing.

Dr. Stephen Kidd, Head of Sales and Marketing at PowerPhotonic, explains, “LIDT is an optical performance parameter that determines the level of power an optical component can handle before damage occurs, with the failure mechanism usually resulting from residual heat, caused by laser beam absorption. The high LIDT measurement demonstrated by PowerPhotonic is market-leading and is a result of the exceptional quality of our optics; a combination of the material used, its purity, substrate processing effects, surface roughness and the impact of coatings. In high-power laser applications, a high LIDT measurement for the optics means the maximum possible power can be delivered by the laser system, with reduced risk of failure.”

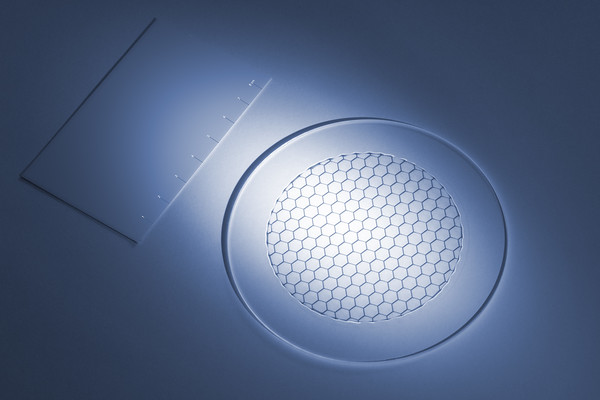

PowerPhotonic optics are manufactured from the highest grades of fused silica; have the smoothest, truly freeform surfaces possible; and are finished with specialist coatings aimed at ensuring best-in-class LIDT. PowerPhotonic’s continuous wave, LIDT measurements exceed 100kW/cm. For pulsed lasers, measurements are between 5 and 12 J/cm², at 1 nanosecond, and between 0.5 and 0.8J/cm², at 1 picosecond.